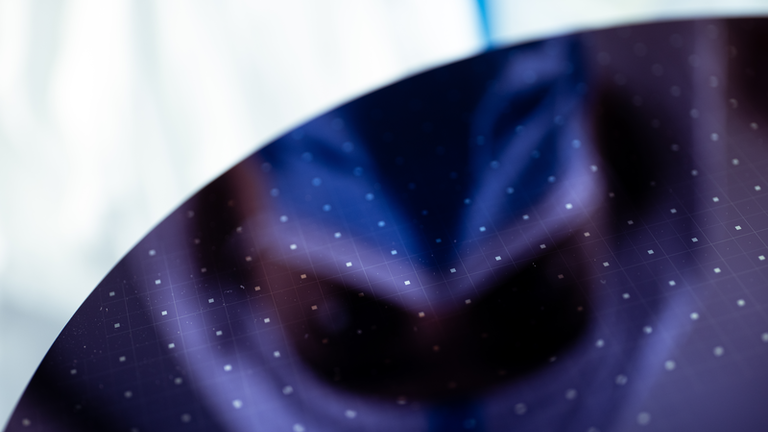

enScribe™

A customer driven approach

Air Liquide initiated development of new etch materials, combining R&D efforts in the US and in Japan with operations in affiliates and active partnership with a number of Universities, equipment manufacturers, and leading edge end customers.

Air Liquide R&D research centers have invested in the competency and capabilities for accelerated development and screening of over a hundred potential molecules. Our customers are fully integrated in this iterative process.

Fighting the Global Warming effects

The semiconductor industry is also concerned with the environmental effects of process materials. The enScribe™ portfolio brings environmental benefits, as its products are designed to reduce the Global Warming Potential (GWP) impact typically associated with most contemporary gases used in etch processes.

Innovative molecules for etching challenge

Fabrication of semiconductor device structures requires several gas phase etching processes for controlled removal of materials in order to create specific architectures. Shrinking dimensions and increasing device complexity bring technological challenges in the etch process. As a result, innovative etch molecules are needed to overcome integration and design challenges, and to enable the progression to advanced nodes.